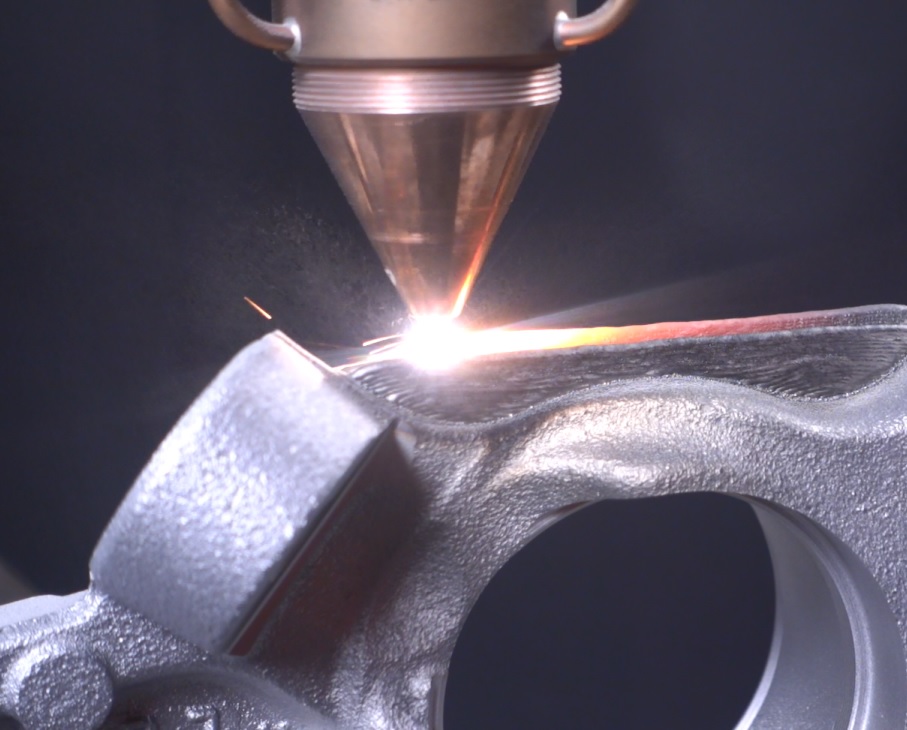

Additive Manufacturing

Additive Manufacturing and 3D Printing : FEA Based Design and Optimization with Simufact, Abaqus, ANSYS

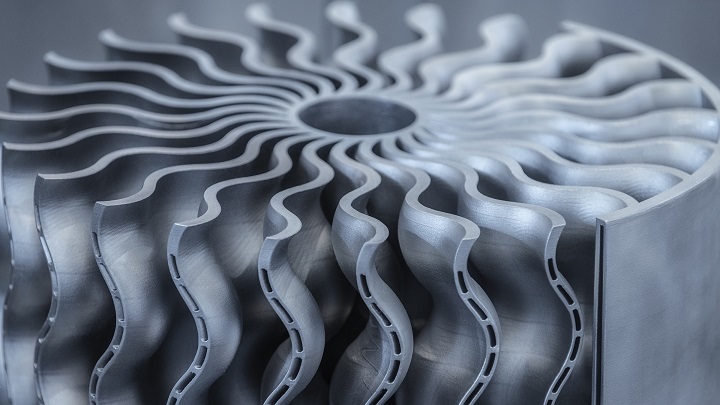

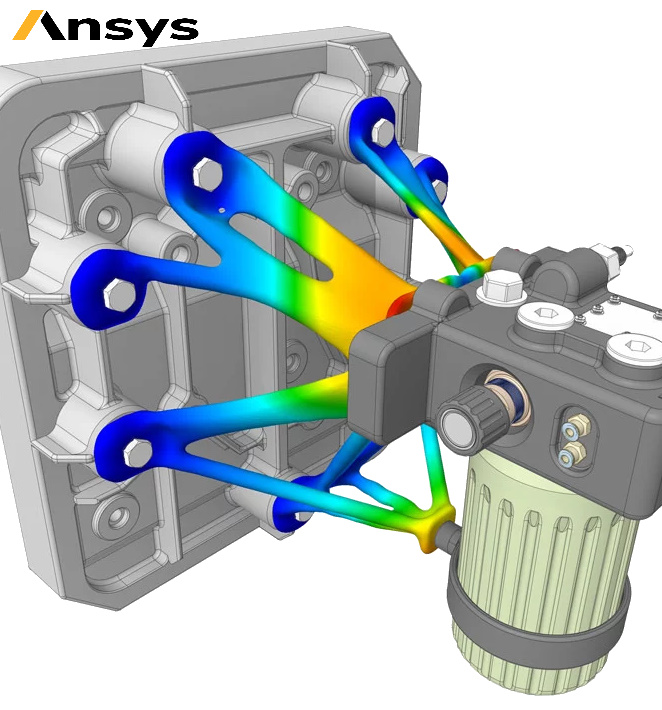

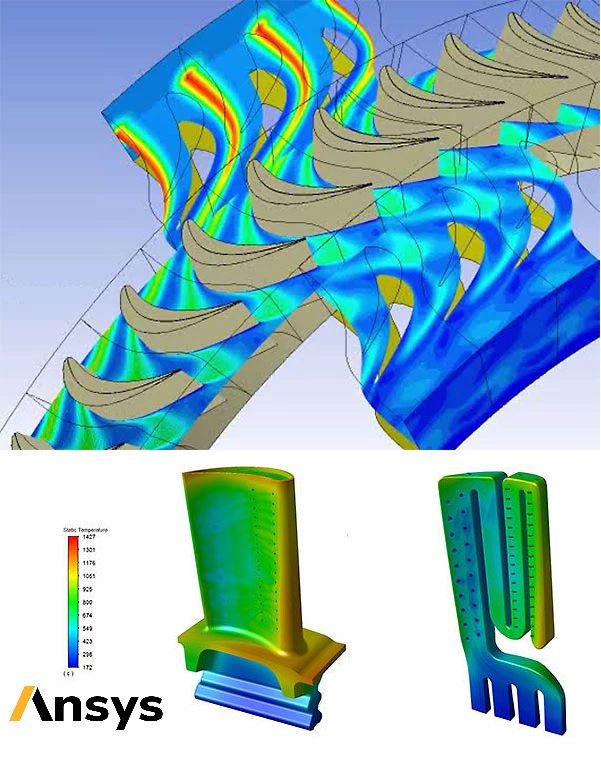

Nonparametric optimization techniques such as artificial intelligence (AI) can be used in conjunction with finite element analysis (FEA) to further optimize designs for AM. AI can help identify the most critical design parameters and their optimal values, while FEA can be used to simulate the performance of the design under various loading conditions. Together, these tools can help engineers create parts that are not only lighter and stronger, but also tailored to specific applications.

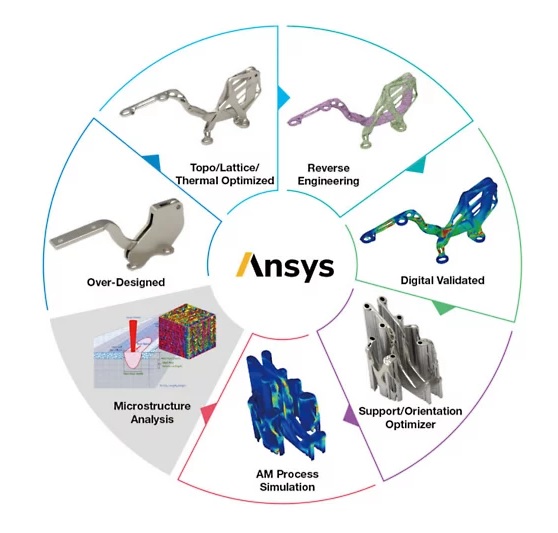

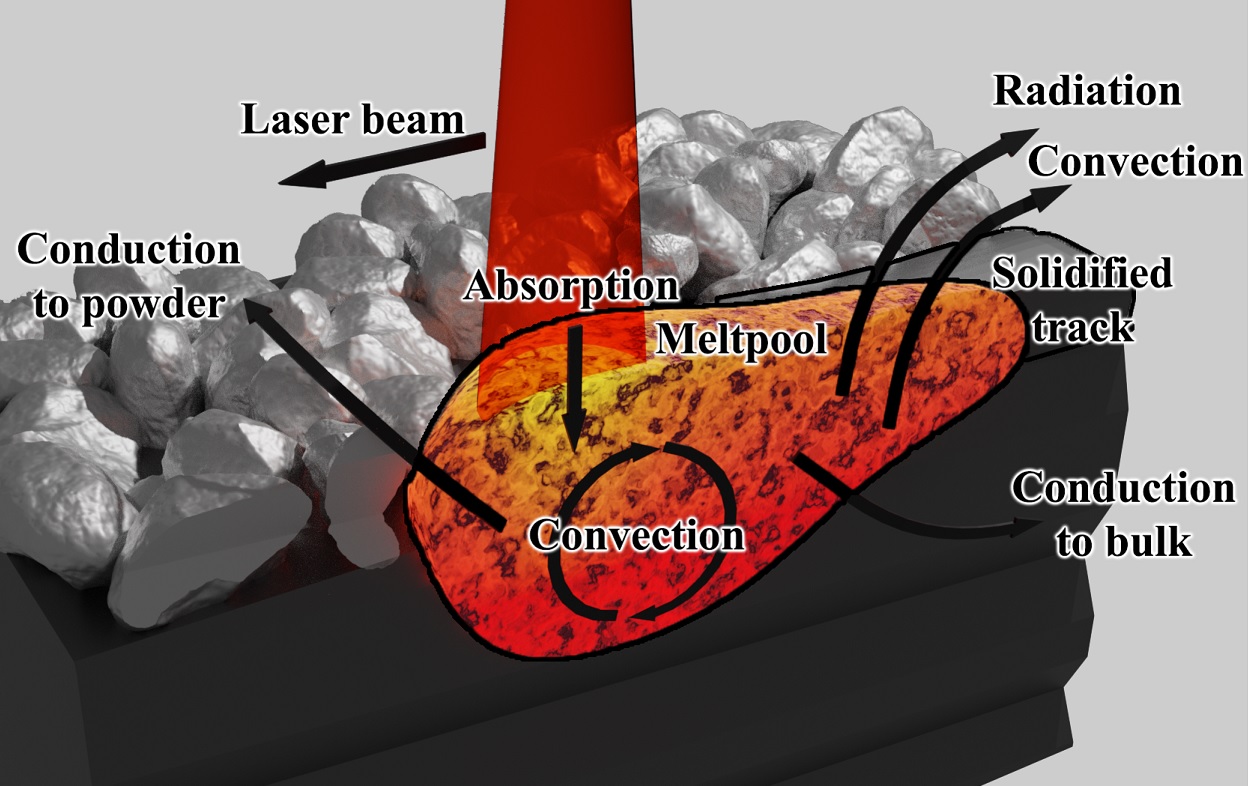

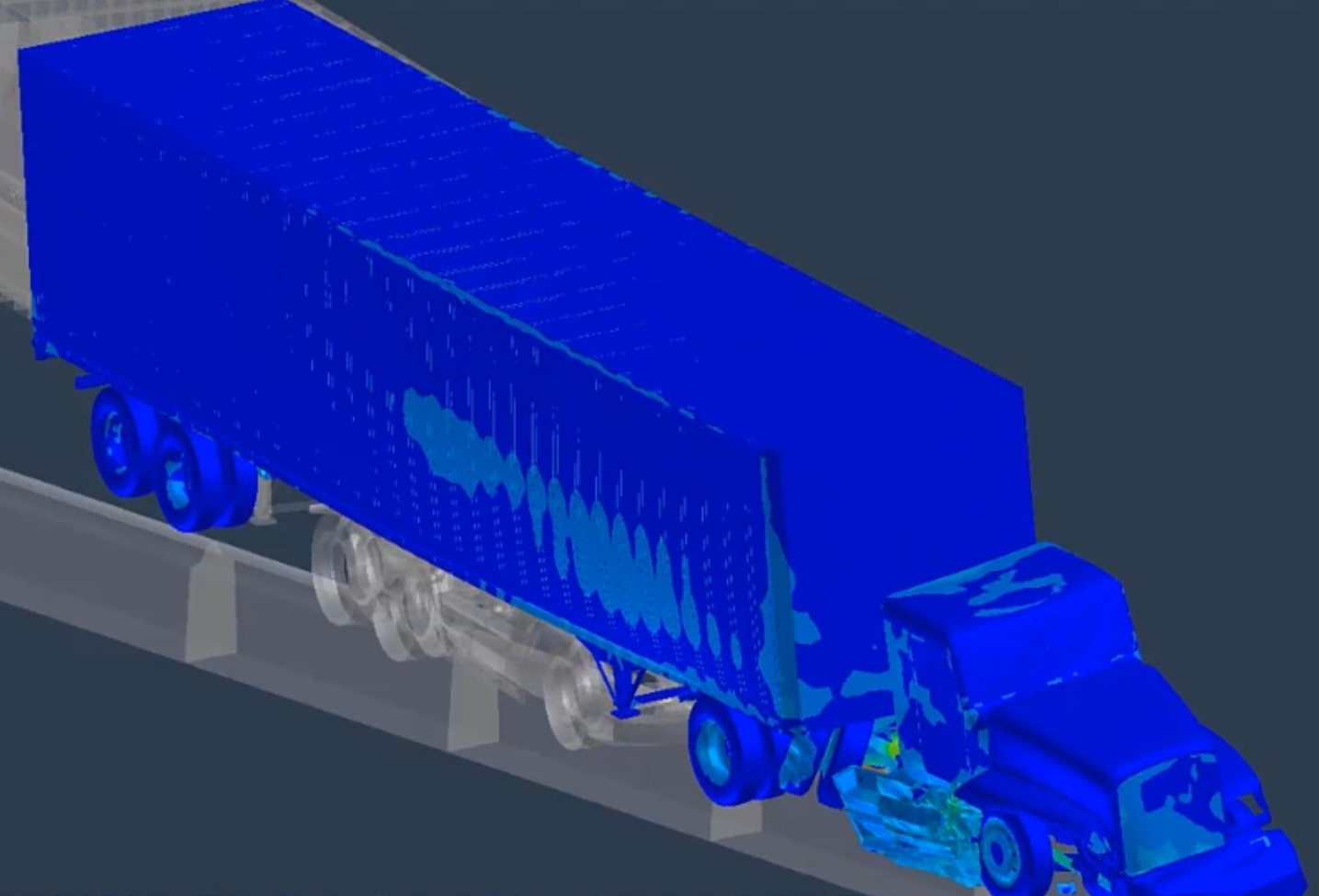

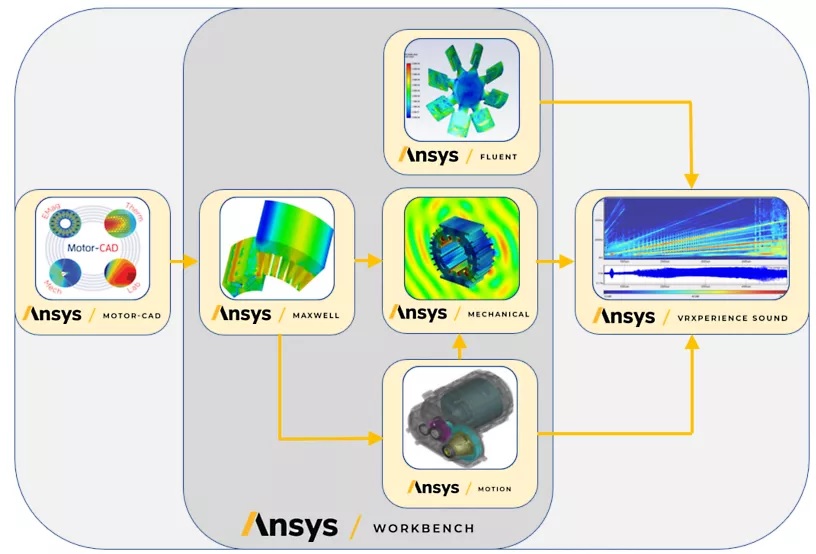

Furthermore, AM simulations with advanced package such as Ansys can be used to assess the quality of finished parts before they are manufactured, reducing the need for costly physical testing and prototyping. By simulating the entire manufacturing process, including the effects of material properties, process parameters, and part geometry, engineers can identify potential issues and optimize the process to improve part quality and reduce the risk of failure.